40 Reasons: Why Allard AFOs Continue To Be #1

Allard has more than two decades of experience in manufacturing and selling Carbon Composite AFOs and have manufactured more than million braces during these years. Continuous investment in R&D and marketing activities have made substantial contribution to the success as well.

Manufacturing

#1 High Tech Manufacturing Site

We have a Fiber Composite standalone manufacturing facility, dedicated 100 % to composites. This eliminates potential contamination from non-fiber manufacturing during the prepregs' curing process.

#2 High Quality Production Molds

Our molds for the products are developed in CAD drawings and made only of the highest quality aluminum. Each mold is refurbished on a frequent schedule to maintain consistent perfect quality.

#3 Precision Cutting

The prepreg sections used in our products are cut on a high precision Cutting Table.

#4 Highly Skilled Experienced Technicians

The proprietary layup methods are only performed by highly skilled and experienced technicians that require at least 6 - 12 months of basic training and depending on segment in the production line, at least another 6 months to become fully trained to manufacture one type of Allard AFO.

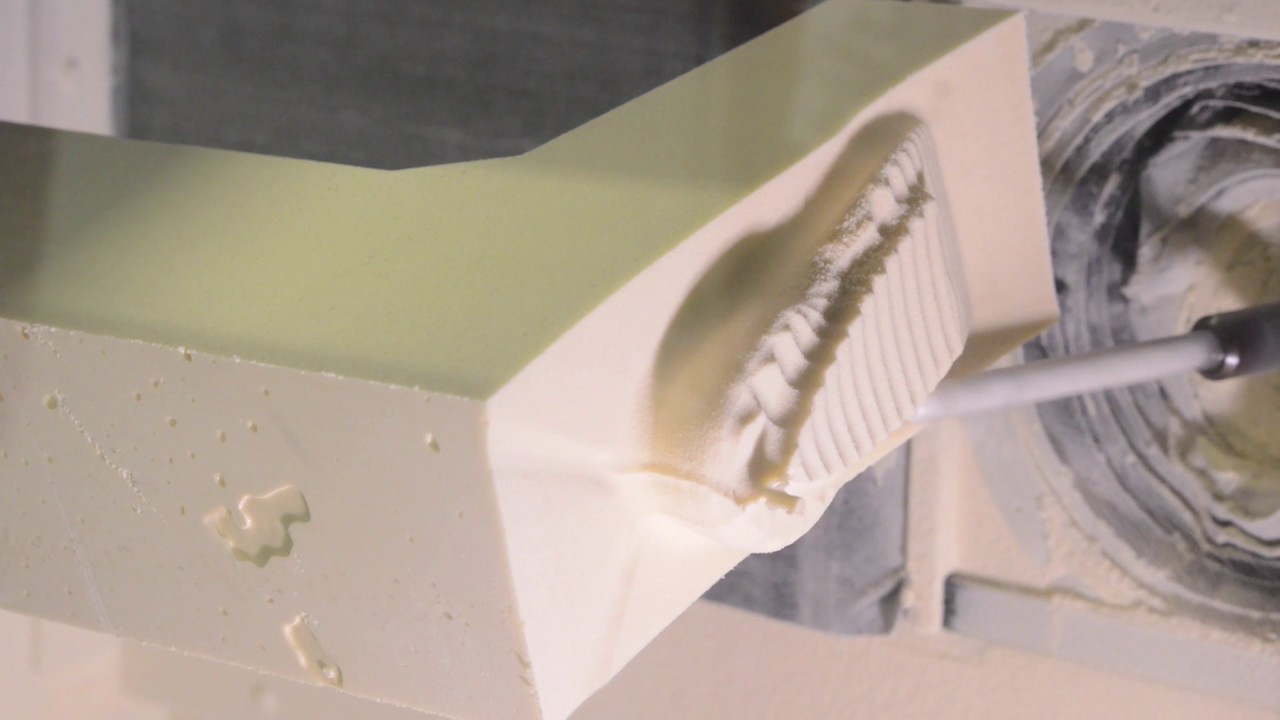

#5 Autoclave Curing

All the Allard AFOs are cured in an Autoclave Pressure Chamber to maintain consistent high quality.

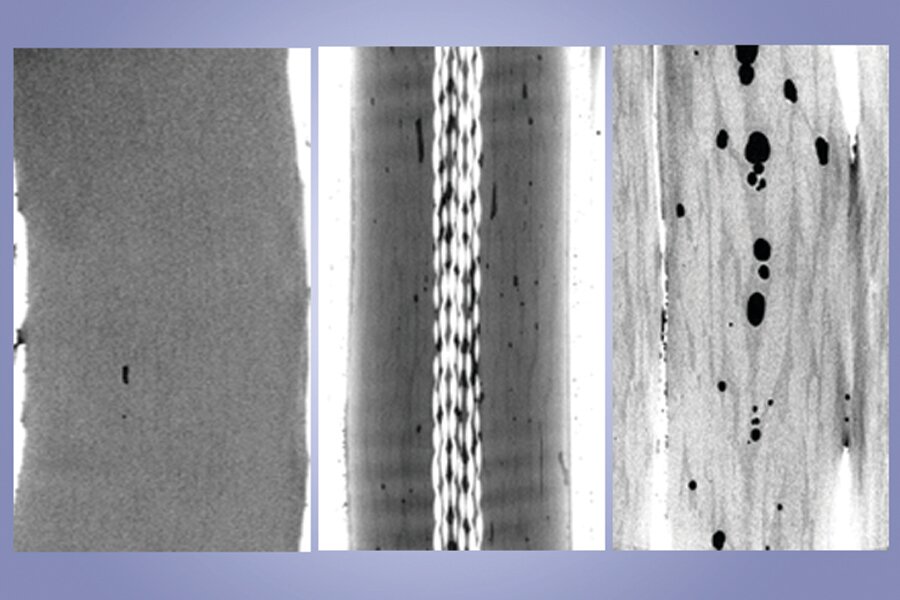

#6 Void Elimination

Allard has invested considerable resources to eliminate voids inside the laminate. Several research papers have shown that voids have a strong negative impact on mechanical properties in composites.

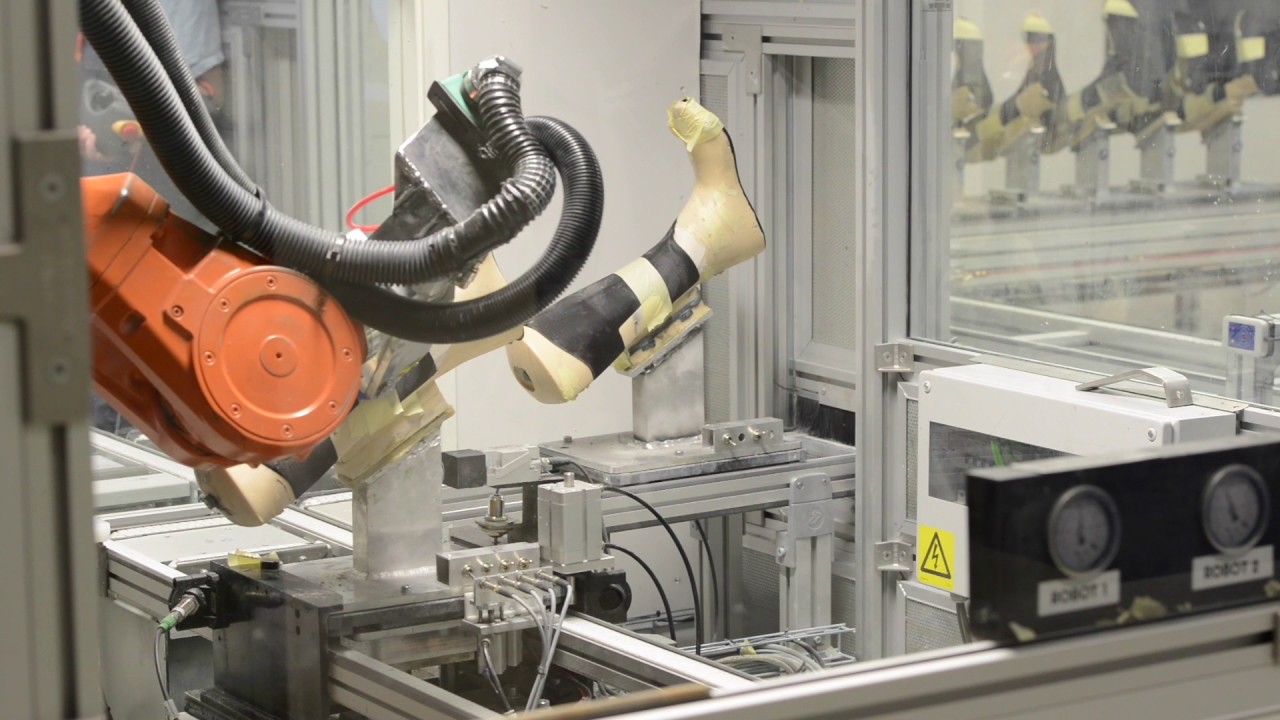

#7 Robotic Cutting

After curing, the product is mounted onto a rail and transported to the robot for a precision cut-out. These robots perform the most accurate and consistent trimming to ensure that each product is exactly the same.

Product Safety

#8 Surface Treatment Method

Before leaving manufacturing, all products are treated with our own in-house developed surface treatment method to make sure the products are smooth, safe and have no rough edges. This is part of our black art - a bit of mystery.

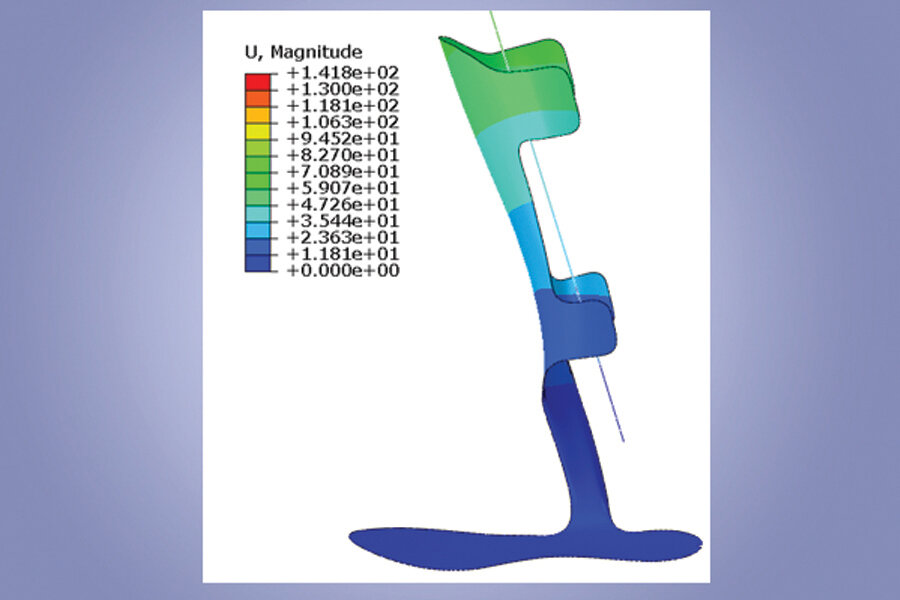

#9 Controlled Fatigue Analysis

The Allard AFOs are designed to minimize the risk of injuries in case of a failure during use.

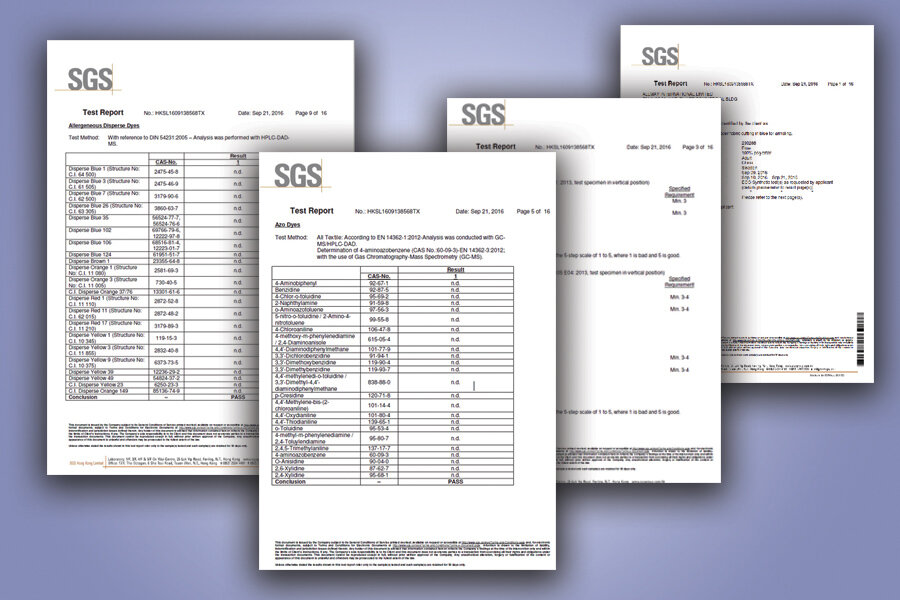

#10 Quality in Soft Goods

Allard has invested substantial resources to ensure that the lining, straps and other soft materials are of highest quality for function and patient comfort. The materials are tested in an external laboratory to ensure safety for both the users and the environment.

#11 Traceability Chain

We can identify every layer of raw material used in our composite braces. Each brace is scanned when shipped to individual customers so it is possible for us to trace any single product and its unique content even after delivery. This traceability chain can continue when customers add to the patient record the peel-off product identification labels provided with each AFO.

Quality Control

#12 Extensive Raw Material Testing

Each batch of raw materials has to pass our inspection for incoming materials before production approval.

#13 100 % Manual Final Inspection

We weigh each product during the finishing and any deviation from tolerances leads to a rejection. Before delivery every product is screened and assessed against our product quality control records.

#14 Random Testing

Scheduled random product testing is performed on all Allard AFOs to ensure that our quality standards are maintained. We have developed testing methods over the last two decades specially designed for composite AFOs. These methods are considered to be company secrets.

#15 Predictable Results

By combining our quality and production know-how, Allard AFOs are easily recognizable and patient outcome can be easily predicted.

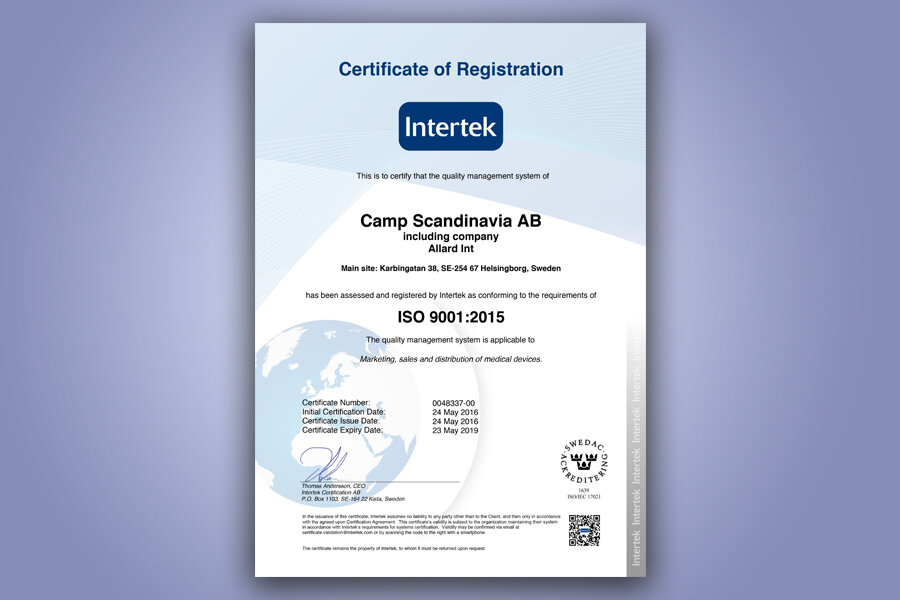

#16 Certified Quality Systems

CAMP Scandinavia/Allard is working with extensive quality systems. Both new product proposals and product improvements are collected from the market to benefit our customers.

Research & Development

#17 Over Two Decades of Development in Composite AFOs

Over two decades of experience and development have made it possible to optimize material, manufacturing and quality aspects to what is known today. One of our company Cornerstones is “Continuous improvement” so tomorrow we know we will make an even better product.

#18 Exchange of Composite “Know How”

Allard has for over two decades been working closely and extensively with the leading global research institutes and suppliers within the composite world.

#19 Allard Laboratory

Before launching a new Allard AFO the product is designed and tested in the Allard Lab. Over more than two decades the Allard laboratory has continually been expanded with equipment and software designed for the sole purpose of analyzing composite AFOs.

#20 Clinical Patient Testing

Over the years we have discovered that users of our products can perform activities with the products that our machines cannot anticipate. Therefore real life patients in safe environments are continuously testing our existing products for research purposes or prior to introduction of a new product.

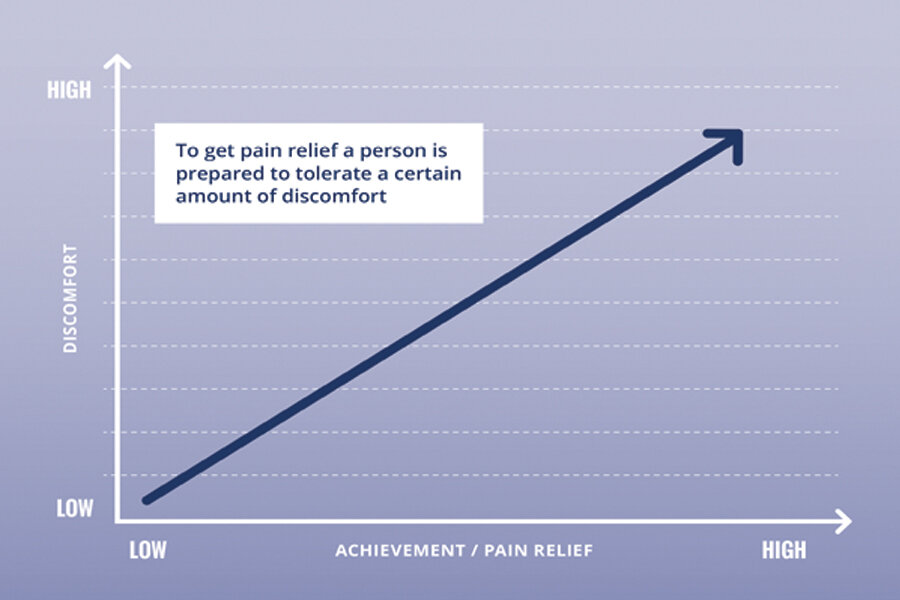

#21 Patient Compliance

Our products shall live up to the users expectations. It is not the user who should adapt to the product.

#22 Continuous Product Expansion

In over two decades we have expanded our product range with approximately 28 products and accessories.

#23 Accessories to Meet Patient Needs

We have an extensive variety of accessories to the Allard AFO products, which means you can choose different interfaces and covering material to meet your patient’s specific needs.

Product Function

#24 Custom Fabrication

All humans are different and some patients do not always fit the standard properties. We have a system based on many years’ experience which provides the customer an opportunity to have us fabricate a custom ToeOFF® or BlueROCKER®. They can use a scanner, plaster or measurements for ordering.

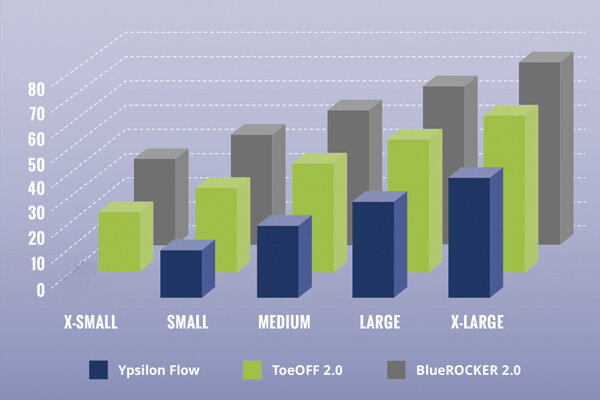

#25 Gradated Dynamics

Allard AFO products offer a range of gradated dynamics from the most dynamic Ypsilon® FLOW to the sturdy BlueROCKER®. The dynamics of the product is dependent on brand and size.

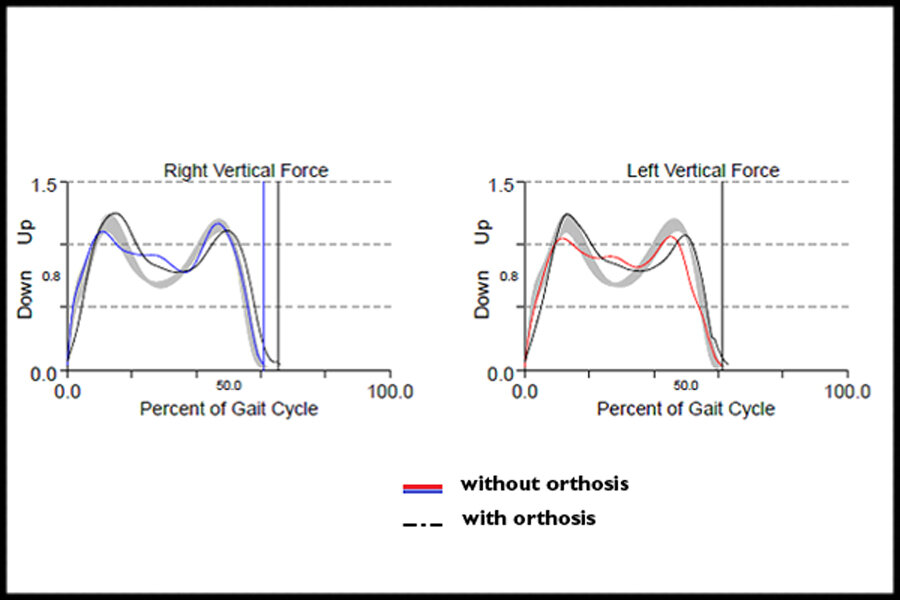

#26 Smooth Transition in Stance Phase

Over the years we have increased our understanding of impaired gait, recognizing the importance of dynamic instead of static. This understanding has helped Allard to make the transition phases from stance even smoother.

#27 AFOs for Different Patient Groups

Through our wide range of products we can offer support to users whose function improve by a brace as well as those who deteriorate in their disease. Our portfolio also allows children to grow with our products, and individuals to gain or lose weight.

#28 Neither Weight nor Size are a Limitation!

No matter if your patient is short or tall, big or small – size and weight are not a limitation for Allard AFOs.

#29 AFOs with Function throughout Gait Cycle

Most AFOs focus on foot drop during Swing Phase, being only 40 % of the Gait Cycle. Considering Stance Phase being 60 % of the gait cycle, Allard AFOs are developed also to support during Mid-Stance and 3rd Rocker propulsion.

Sales & Education

#30 Continuous Education

Since the introduction of the ToeOFF brace, Allard has educated more than 100,000 referral sources worldwide on the function and benefits of using a Composite AFO.

#31 Trying before Buying

By introducing Assessment Orthoses, the orthotist can educate and interact with Physical Therapists. We know our braces are not for everyone, but we are not afraid to let users and Physical Therapists try before making a decision.

#32 Patient Awareness

In 2013 Allard formed “GetBackUPToday” to raise public awareness about using AFOs with foot drop. This has established 36,000 followers on Facebook and created 404 news reports. Out of 13 TeamUp Co-captains, 3 athletes using Allard AFOs competed in the latest Paralympics in Rio de Janeiro and brought home 1 gold and 3 silver medals.

#33 O & P Partnership

We truly believe that the fitting and alignment considerations requires the expertise of an orthotist. Therefore, as your O & P Partner, we sell the brace worldwide only to certified orthotists.

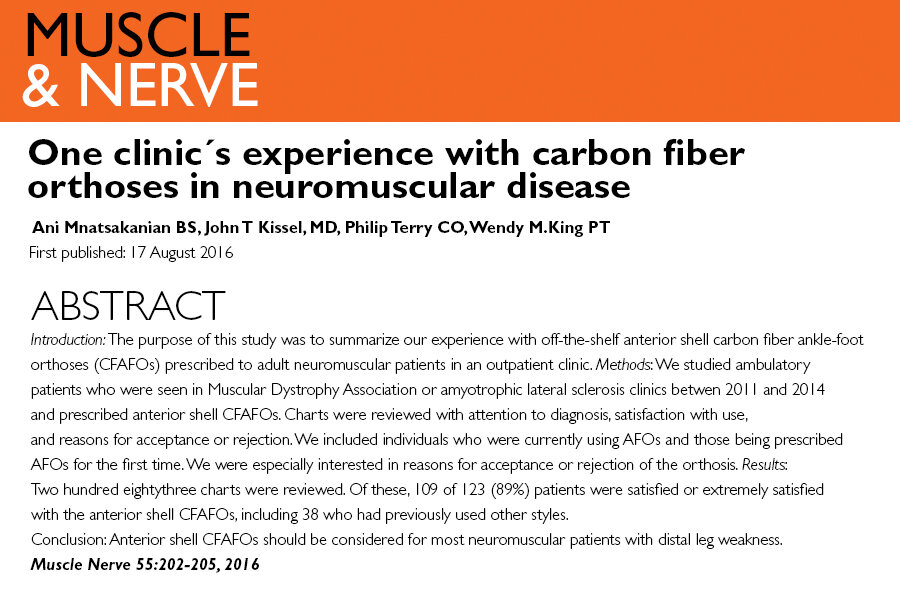

#34 Outcome Evidence

Allard AFOs have been evaluated in numerous studies to prove the benefits of Carbon Composite AFOs, also the high outcome of satisfaction of using the product.

#35 Generous Warranty

We are, to the best of our knowledge, offering the most generous warranty terms in our industry.

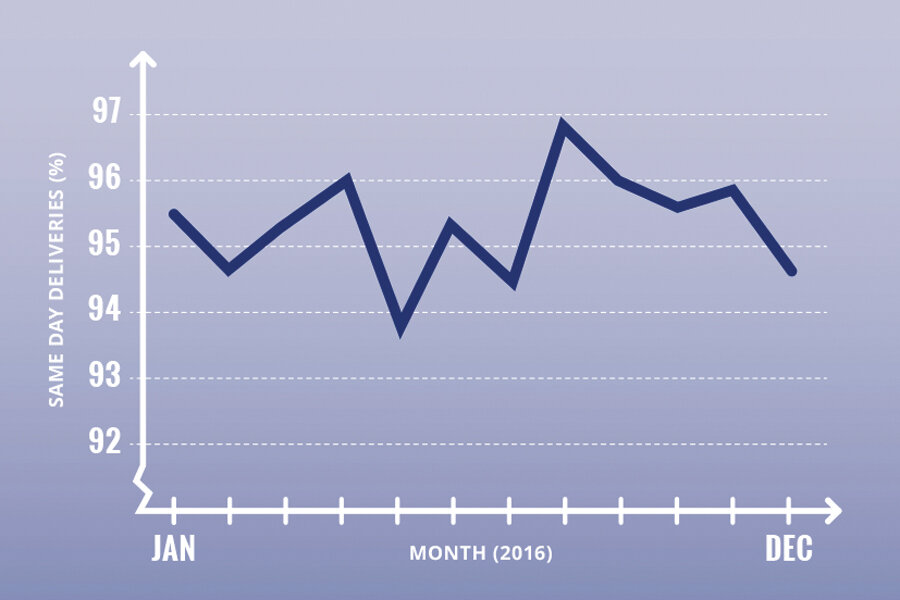

#36 High Service Level

The Allard Company group have a high Service delivery level. Over the past 5 years the service level for standard Composite AFOs has averaged 95 %.

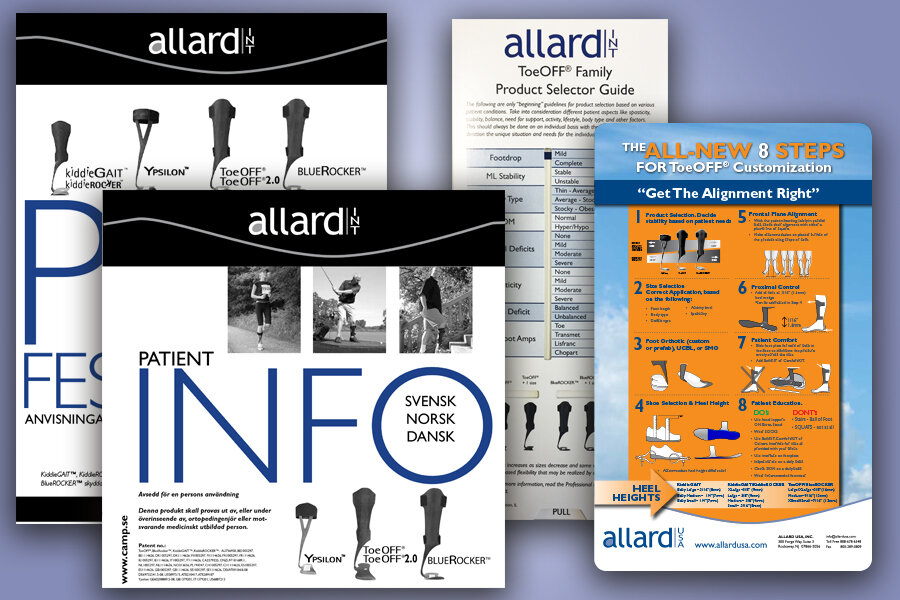

#37 Support Materials

We provide top of the line support materials to help our customers select the best product and properly fit our products, and to help them educate their referral sources and patients.

Social Responsibility

#38 Charity Donations

Allard donates money to Dralla Foundation, our Charity organization, for each AFO sold. Dralla's mission is to “Give individuals with physical challenges an unforgettable day!”. Dralla has supported 68 "unforgettable day" events since the start in 2011. Visit dralla.org.

#39 Environmentally Responsible

One of our company’s 4 cornerstones is “Responsibility for Environment”. Environment is not something that should be taken for granted. In everything we do, work methods and processes, we endeavor to be environmentally friendly. Producing a carbon composite AFO consumes considerable energy. To ensure that we as an organization do not drain the earth’s resources to function and manufacture our products, we made the significant investment to operate as much as possible via renewable energy sources (wind turbines). The result is we neither pollute the air nor have a negative impact on global warming.

#40 Partnership with Patient Organizations

We partner with national and international non-profit organizations whose members may benefit from our products to help increase awareness of the functional benefits of carbon composite AFOs.